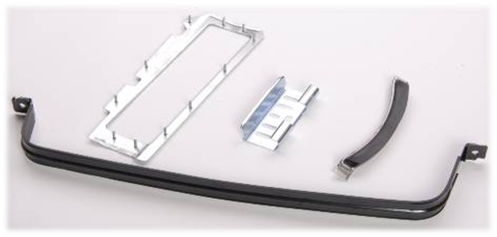

Metal Stamping

Quality American Metal Stamping Services

Stamped Products Incorporated provides quality-backed metal stamping services for a wide range of commercial and industrial production applications. Our facility offers both transfer press and progressive die metal stamping capabilities accommodating part sizes up to 48” in width. We have the capacity to efficiently tackle both low-volume and high-volume metal stamping runs according to the unique needs of your project.

Transfer Press and Progressive Die Stamping Solutions

SPI utilizes a wide range of stamping presses to provide both the flexibility and efficiency that your unique production application demands. Our in-house metal stamping department is integrated with transfer presses, progressive die presses, and hand transfer lines.

Our company is backed by a long history as one of Alabama’s leading metal stamping providers. To deliver the most versatile industrial press services possible, SPI has continued to evolve with new industry standards and materials, such as high-strength and dual-phase materials, stainless steel, and aluminum.

Move Your Custom Stamping Project Seamlessly to Our Facility

As one of the greater South’s leading metal stamping shops, SPI recognizes all the benefits of streamlining your project for both timeliness and simplicity. When we take on your production, we strive to immediately address every pain point you experienced with your previous vendor.

We know that a quick ramp-up to production and lighting-fast turnaround are key to your project’s success. SPI’s fully outfitted press department backed by our complete in-house tool room allow us to seamlessly transfer your program to our production line with far less downtime than most of our competitors.

Our Key Assets, Equipment, and Metal Stamping Capacities

- A full-service department outfitted with metal stamping presses that range from 300 – 660 ton capacity.

- Progressive die stamping presses with servo feeders offering feed width up to 48” and bed sizes up to 144″ x 60″.

- 660 ton blank-fed transfer press with a bed size of 181″ x 72″.

- Hand transfer tandem line.

- Fully outfitted tool room for die repairs, upgrades, and maintenance.

- Value-added turnkey assembly solutions to streamline your stamping project under one roof.

Versatile Transfer Press Services and Progressive Die Stamping

SPI specializes in quality-backed metal stamping services for a wide range of commercial and industrial applications. From automotive and agricultural parts manufacturing to consumer appliances and HVAC systems, we bring diverse production experience to your project. Our versatile stamping press and progressive die tooling can accommodate component sizes up to 48” in width.

Transfer Presses

- SPI’s transfer press capabilities are a cost-effective manufacturing solution for complex industrial parts and high-volume production applications. Our facility utilizes a blank-fed servo press that delivers 660-ton capacity. Our transfer press operates with Linear Transfer’s innovative automation system to optimize production and maximize throughput with a speed of 15-30 strokes per minute.

Progressive Die Presses

- SPI offers custom progressive die stamping services ideal for your more complex metal stampings. Our progressive tooling solutions automate numerous stamping processes, delivering the utmost in precision and repeatability.

While the upfront cost of developing custom progressive tooling can be prohibitive for low-volume projects, the speed, accuracy, and efficiency afforded through SPI’s progressive stamping services make them ideal for high-volume productions and long-term contract manufacturing projects.

Superior Metal Stamped Quality and Consistency

SPI strives to offer unbeatable quality, consistency, and lean manufacturing efficiency through all of our metal stamping services. Our integrated robotic welding department and turnkey assembly operations enable us to streamline your project under one roof. Our flexible production solutions are supported by a robust quality control system which is certified to ISO 9001:2015 standards.