Our Services

Quality Metal Stamping and Robotic Welding Services

Stamped Products Incorporated is an ISO 9001:2015 certified American manufacturer specializing in metal stamping services and complete welded assemblies for the automotive industry as well as a range of other quality-focused production applications.

- Automotive Manufacturing

- Agricultural Equipment

- Consumer Appliances

- HVAC System Components

- Utility Task Vehicle (UTV) and All-Terrain Vehicle (ATV) Parts

SPI strives to deliver unbeatable manufacturing quality and consistency with competitively priced products that are delivered on time, every time.

METAL STAMPING SERVICES

SPI offers quality-backed metal stamping services for a wide range of commercial and industrial production applications. Our facility specializes in both transfer press and progressive die metal stamping projects accommodating part sizes up to 48” in width.

Transfer Press Solutions

Our integrated transfer press department utilizes a blank-fed transfer press with a capacity of 660 tons. Our press operates with Linear Transfer’s servo automation system to optimize production with a speed of 15-30 strokes per minute.

Progressive Die Stamping

Supported by our expert in-house tooling capabilities, SPI’s progressive stamping services enable us to streamline numerous stamping processes into a single die, providing the utmost in accuracy and repeatability for your products.

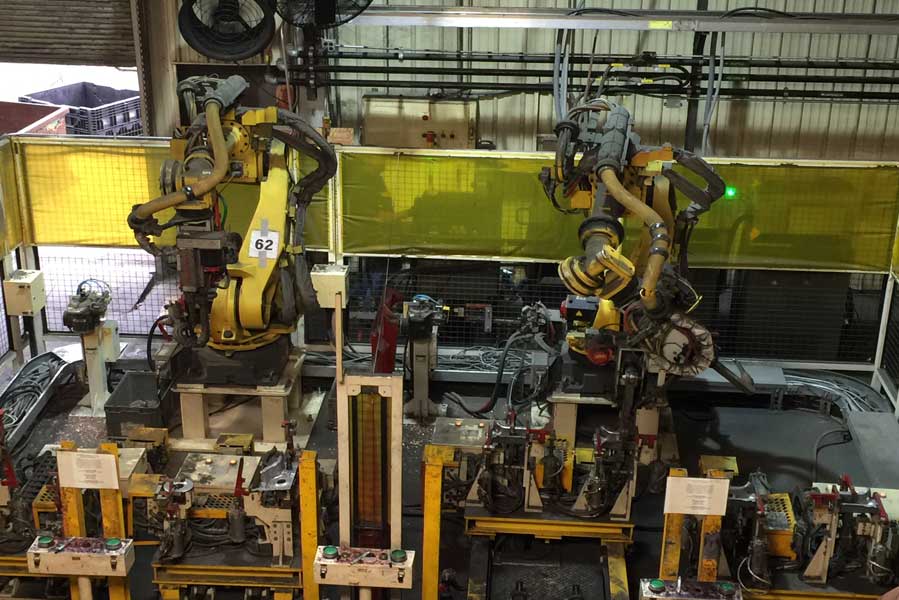

ROBOTIC WELDING SERVICES

SPI provides extremely accurate and efficient robotic welding services for finished components and subassemblies. Our automated welding solutions are engineered to deliver the precision and consistency demanded by some of the industry’s most challenging production applications.

Value-Added Assembly Solutions

Our value-added assembly services provide your project with a streamlined solution for your turnkey assemblies and subassemblies. Utilizing either our in-house metal stampings or third-party component sets, SPI performs detailed assembly processes in accordance with ISO 9001:2015 quality control specifications.

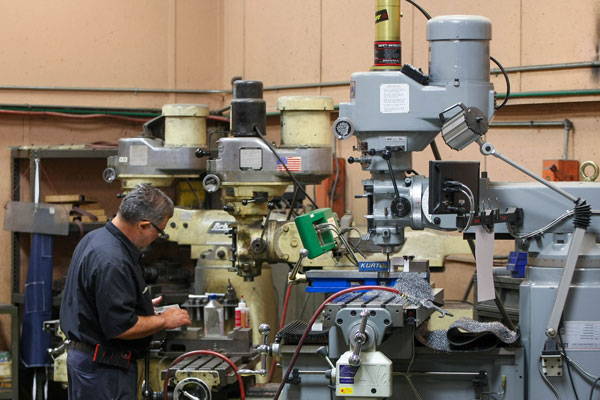

IN-HOUSE TOOL ROOM

SPI offers the added benefit of having an on-site tool room in our facility, minimizing any downtime and bottlenecks in production. This enables us to provide quick and efficient tool changes, as well as repairs, to keep your custom stamping project on track and ahead of schedule. Our in-house tool room is equipped with various CNC mills, wire EDMs, and precision grinding capabilities. We also have the capability with our FARO arm to develop reverse-engineering solutions.